Start by typing in the artist:

So, we all know where babies come from and if you don't then Daddy sticks his finger in Mummy's bellybutton, says a magic word and then 9 months later a penguin leaves a baby in your garage next to the lawnmower. Or something like that.

Anyway one thing I bet you didn't know is how PS3 games and Blu Rays are made, well fear not! For in true Willy Wonka fashion I have a golden ticket and I'm going to share the secrets of how PS3 games and those new-fangled Blu Ray discs are manufactured at Sony's new Australian factory over in Sydney.

Yes, that's right. It's a Tuesday afternoon and you know what that means? WoW servers are down, I have no real life to speak of as the sun burns my soul, I have absolutely nothing to do, and besides, you can only masturbate so many times in an afternoon. So ladies and gentlemen, children of all ages gather around, keep your hands in the vehicle at all times and no eating any of the exhibits. Come and learn something of absolutely no use and humour me. Click below to see the magic unfold before your very eyes.

First off, the technicians must enter the production room via a chamber that blasts their bodies with air to rid them of dust and contaminating agents that might corrupt the discs and cause all manner of molecule related mischief. Now, whether or not these bodies are naked or not isn't clear but one can only hope....

Contrary to popular belief these Harry Potter discs aren't made from either wizardary, the blood of Slitherin scum or the farts of angels they're actually made from good old polycarbonate (the same stuff they make those thick unbreakable windows inside buses and trains) granules which are delivered to the factory by truck and stored in a silo until needed.

The polycarbonate granules are then transported all around the factory by tubes until they end up in a device called a Hopper. This measures them out evenly and really doesn't get any more exciting than that.

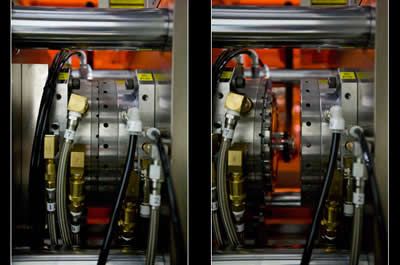

After the Hopper, the polycarbonate is reduced to a gloopy melted mixture that is fed into a mould that compresses the mixture into a disc shape and creates the first layer of data in the process. Whether or not this mould has the power to squash a Terminator's head is unclear, but a mould like this probably did squeeze out that insipid Terminator Salvation game like a particularly unpleasant turd.

This is where things start to get shiny, this machine performs a process called Sputtering, which is NOT a strange sexual practice involving phlegm but is actually where a layer of silver which is 90 angstroms thick is added to the disc. Science buffs out there will know that an angstrom is a measurement equal to one millionth of a centimetre, science buffs that don't are endangering us all.

This machine though has an electromagnetic field around it that is so powerful it can actually affect pacemakers.

Here, the sputtered (no, it's still not a phlegm based sexual practice) disc is coated in a layer of UV (ultraviolet) resin and then cured with light. From here it's off to the next stage where the second layer of data is embedded.

This is the Hard Layer phase where the disc is given another coating of that UV resin and a final protective layer to protect the finished product from grubby hands and spillages before being checked for any disc corrupting bubbles.

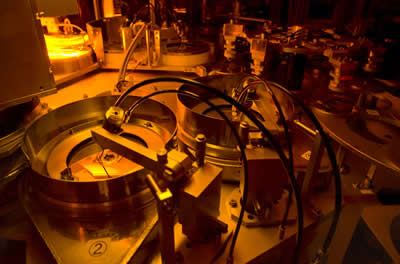

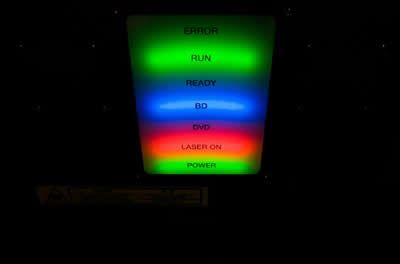

Now, here is where they check the disc and make sure it works properly by checking the data integrity of each disc through playback and scanning. Let us pause for a moment and think of the severe hardships someone must have had to endure when Sex and the City came out on Blu Ray. Sir or Madam, I salute you.

Now, you know what a Blu Ray looks like naked and without it's artwork. After being checked for any errors they either end up here to be loaded onto a printer to have their modesty protected or end up in the firey depths of Blu Ray hell if deemed faulty.

These are the master plates for the artwork for each disc. And they are all stored in this rack ready for printing.

Ever wondered how those discs are actually printed? No? Well, tough! I'm telling you anyway. But they're printed silkscreen style. The artwork is broken down into 4 colours which are black, cyan, magenta and yellow that are applied separately in layers and then treated with ultra-bright light which sets the ink and produces a final image.

Now, we have the finished discs they end up being taken to an assembly packing line where they get matched with their case, inserts and covers before going off to the final packaging machine which gets them all ready for shipping, sale and entertaining the masses.

This is where the final bit of magic happens. Discs and inserts are placed into boxes and sealed.

At full pelt this machine can package 4500 Blu Ray discs per hour, but even the most skilled of cellophane unwrapping experts can only open about 2 of the bloody things an hour.

Around two thirds of these discs are films and the rest games.

Before we go, don't forget to wave to the nice people who provide you with so many hours of entertainment. No, they're not Oompa Loompas and no you can't have one, so don't ask!

So now you know how Blu Ray discs are made. Now go and think about what you've learned and then never have an opportunity to use it.